This article was updated in January 24, 2026 with new products and information by Mark S. Taylor

Your car’s fuel system has seven essential parts working together to deliver the right amount of fuel to your engine at the right time. The essential fuel system components keep your car running smoothly. I have spent years fixing these complex parts. In this guide, I will explain what each part does and how to maintain them. You will learn about repair costs and warning signs. Let’s explore the heart of your car.

Contents

What Is a Fuel System?

The fuel system stores and delivers gasoline to the engine for combustion.

It is the heart and veins of your vehicle. It pumps energy to the engine to keep it moving.

Fuel System Purpose

It ensures your engine gets clean fuel at the perfect pressure.

- Stores fuel safely: It keeps volatile gas away from hot engine parts.

- Delivers clean fuel: It filters out dirt that could ruin the engine.

- Controls pressure: It keeps the flow steady, even when you speed up.

- Optimizes mixture: It matches the fuel amount to the air entering the engine.

- Reduces emissions: It prevents harmful gas vapors from escaping.

How the Fuel System Works

It is a continuous loop of pressure and flow.

- Storage: Fuel sits in the tank.

- Pressure: The pump pushes it forward.

- Cleaning: The filter catches debris.

- Regulation: The regulator sets the pressure.

- Injection: Injectors spray it into the engine.

- Combustion: The spark plug lights it up.

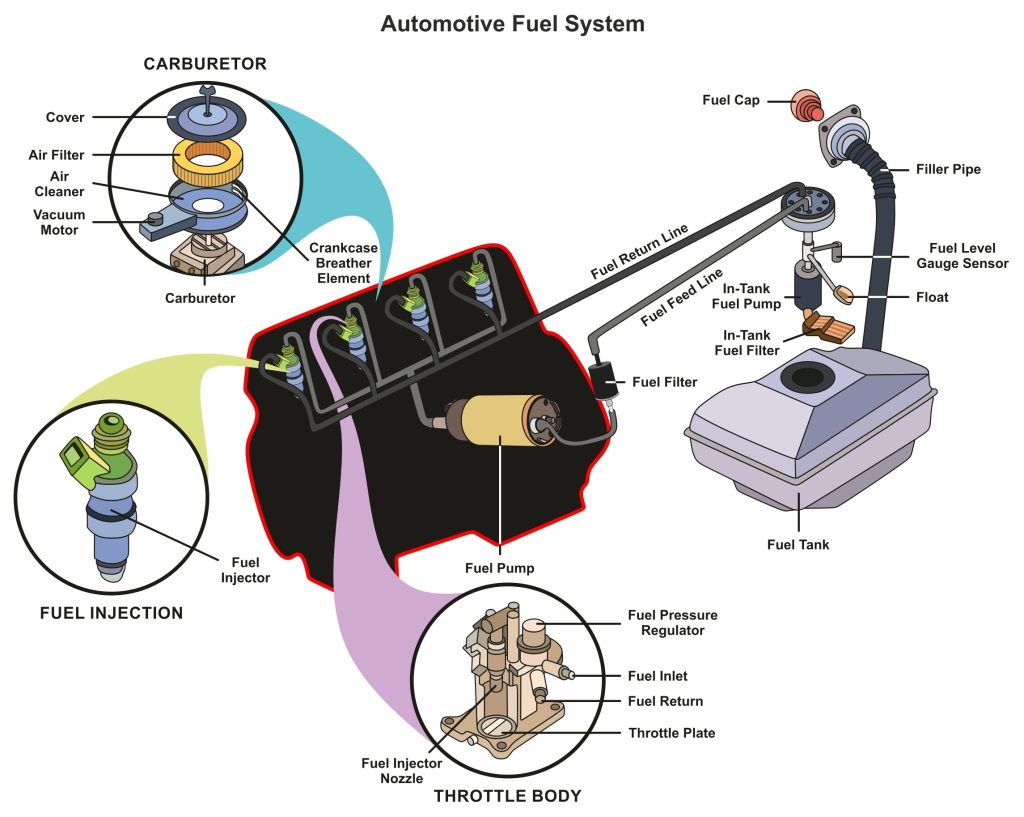

Diagram: Essential Fuel System Components

A visual map helps you see how fuel travels from the rear to the front.

Component Flow Path:

- Storage: Fuel Tank (Rear)

- Delivery: Fuel Pump, Fuel Lines (Underbody)

- Cleaning: Fuel Filter (Underbody or Tank)

- Regulation: Fuel Pressure Regulator (Engine Bay)

- Distribution: Fuel Rail (Engine Top)

- Injection: Fuel Injectors (Cylinder Head)

- Control: Engine Control Unit (ECU)

The 7 Essential Fuel System Components

These seven parts form the backbone of your vehicle’s power supply.

1. Fuel Tank

The fuel tank is the secure reservoir that holds your gasoline or diesel.

It is usually mounted under the rear seats. Modern tanks are made of high-density plastic. This prevents rust and handles crashes better than metal.

- What It Does: It holds fuel and catches dangerous vapors.

- Key Features: It has a filler neck for gas nozzles and a vent to stop pressure buildup.

- Signs of Problems: You might smell raw gas near the back of the car. A check engine light for an “EVAP” code often points here.

- Lifespan: 10 to 20 years. The tank rarely fails, but the sensors inside do.

- Replacement Cost: $400–$1,500+.

2. Fuel Pump

The fuel pump creates the pressure needed to move gas to the engine.

Most modern cars have an electric pump inside the gas tank. The gas actually cools the pump motor. That is why running on “Empty” is bad for it.

- What It Does: It pushes fuel from the back to the front at 30–80 PSI.

- How It Works: An electric motor spins a turbine. This forces fuel into the lines.

- Signs of Problems: You might hear a loud whine from the tank. The car may sputter at highway speeds.

- Lifespan: 100,000 to 150,000 miles.

- Replacement Cost: $400–$800.

3. Fuel Filter

The fuel filter traps dirt, rust, and paint chips before they hit the engine.

Think of it as a coffee filter for your gas. If dirt gets past this, it will clog the tiny holes in your fuel injectors.

- What It Does: It protects sensitive engine parts from debris.

- Types: In-line filters are under the car. In-tank filters are part of the pump.

- Signs of Problems: The car feels sluggish. It acts like it is running out of gas even when full.

- Lifespan: 20,000 to 40,000 miles. Some are “lifetime” filters inside the tank.

- Replacement Cost: $50–$200.

4. Fuel Pressure Regulator

This valve ensures the fuel pressure stays constant, no matter how you drive.

If pressure is too low, the engine starves. If it is too high, the engine floods. The regulator keeps it just right.

- What It Does: It balances the flow of fuel.

- How It Works: A spring-loaded valve opens or closes based on engine need.

- Signs of Problems: Black smoke from the tailpipe means high pressure. Stalling means low pressure.

- Lifespan: 100,000+ miles.

- Replacement Cost: $100–$400.

5. Fuel Rail

The fuel rail is a metal pipe that feeds all the injectors at once.

It acts like a small reservoir on top of the engine. It ensures that cylinder #1 gets the same pressure as cylinder #4.

- What It Does: It distributes fuel evenly.

- How It Works: It holds a reserve of pressurized fuel ready for the injectors.

- Signs of Problems: Leaks are the main issue here. You will see wet spots on the engine.

- Lifespan: 150,000+ miles. It is a simple metal part that rarely breaks.

- Replacement Cost: $200–$600.

6. Fuel Injectors

Injectors are tiny electric valves that spray fuel into the engine.

These are the final stop. They open and close thousands of times per minute. They turn liquid gas into a fine mist.

- What It Does: It measures the exact drop of fuel needed for power.

- Types: Direct injection sprays right into the cylinder. Port injection sprays into the intake.

- Signs of Problems: A rough idle or a “misfire” code. See our guide on Symptoms of a Bad Throttle Body to distinguish air issues from fuel issues.

- Lifespan: 50,000 to 100,000 miles. Cleaning helps them last longer.

- Replacement Cost: $100–$500 per injector.

7. Fuel Lines and Hoses

These tubes connect the tank in the back to the engine in the front.

They run under the car. They are made of steel or hard plastic to resist rust and road debris.

- What They Do: They transport fuel safely.

- Signs of Problems: A strong gas smell or a puddle under the car.

- Lifespan: 10 to 15 years. Road salt can rust steel lines.

- Replacement Cost: $100–$400.

Additional Fuel System Components

Modern cars use computers and sensors to refine the process.

Engine Control Unit (ECU)

The brain of the operation.

It reads data from sensors. It tells the injectors exactly when to open.

Fuel Level Sensor

The float in the tank.

It moves up and down with the gas level. It sends the signal to your dashboard gauge.

High-Pressure Fuel Pump

For direct injection engines.

This secondary pump boosts pressure to over 2,000 PSI. It creates the power needed for modern efficiency.

Throttle Body

The air controller.

While not a fuel part, it works with the fuel system. It controls the air that mixes with the gas.

Types of Fuel Systems

Technology has changed how engines drink fuel.

Carbureted Fuel Systems (Pre-1990s)

Old school and simple.

They use suction to pull fuel in. They are easy to fix but waste gas.

Port Fuel Injection (PFI/MPI)

The standard for 30 years.

Injectors spray into the intake manifold. It is reliable and clean.

Direct Injection (GDI/DI)

The modern performance standard.

Injectors spray directly into the explosion chamber. It gives more power and better MPG.

Diesel Fuel Systems

Built for high pressure.

Diesel needs huge pressure to burn. These systems are heavy-duty and robust.

How Fuel System Components Work Together

It is a relay race from the tank to the engine.

The Complete Fuel Delivery Process

- Storage: The tank holds the supply.

- Pressurization: You turn the key. The pump wakes up and pushes fuel.

- Filtration: The filter catches the dirt.

- Pressure Regulation: The regulator steadies the flow.

- Distribution: The rail holds the fuel ready.

- Injection: The ECU says “Go!” The injector sprays.

- Combustion: Boom. The engine turns.

Common Fuel System Problems

Most issues come from dirt or age.

Clogged Fuel Filter

A dirty filter chokes the engine.

- Symptoms: Hard starting or stalling.

- Solution: Swap the filter. It is cheap maintenance.

Weak or Failing Fuel Pump

A dying pump cannot keep up.

- Symptoms: Whining noise or loss of power on hills.

- Solution: You need a new pump.

Dirty Fuel Injectors

Carbon buildup blocks the spray.

- Symptoms: Rough idle or poor gas mileage.

- Solution: Run a cleaner additive or get a professional cleaning.

Fuel Pressure Regulator Failure

Bad pressure confuses the engine.

- Symptoms: Black smoke or a strong gas smell.

- Solution: Replace the valve.

Fuel Line Leaks

Rust eats through metal lines.

- Symptoms: Puddles or smell. This is a fire risk.

- Solution: Replace the rusty section fast.

Fuel System Maintenance Schedule

Prevent repairs with a simple schedule.

| Component | Interval | Service |

| Fuel Filter | 20k–40k miles | Replace |

| Injectors | 30k–50k miles | Clean |

| Pump | 100k+ miles | Replace if noisy |

| Lines | Annually | Inspect for rust |

| System | 30k miles | Add cleaner |

Preventive Maintenance Tips:

- Buy Top Tier Gas: Cheap gas has less detergent.

- Keep It Over 1/4 Tank: This keeps the pump cool.

- Change Filters: Do not skip this cheap step.

- Watch Warning Lights: Check the Master Warning Light immediately if it illuminates.

Fuel System Repair Cost Guide

What to expect at the shop.

| Component | DIY Cost | Pro Cost | Time |

| Fuel Filter | $10–$30 | $80–$150 | 1 hr |

| Fuel Pump | $100–$300 | $400–$800 | 3 hrs |

| Injector (1) | $50–$150 | $200–$500 | 2 hrs |

| Regulator | $50–$200 | $150–$400 | 2 hrs |

| Fuel Tank | $200–$800 | $600–$1,500 | 5 hrs |

Costs vary by vehicle model.

DIY vs. Professional Service

Know your limits before you start.

Good DIY Projects

Safe and easy tasks.

- Changing an external fuel filter.

- Pouring in system cleaner.

- Checking lines for leaks.

Requires Professional Service

Risky or complex jobs.

- Replacing an in-tank fuel pump.

- Replacing high-pressure injectors.

- Dropping a fuel tank.

Safety Warnings

Gasoline is dangerous.

- Disconnect Battery: Sparks cause fires.

- Ventilation: Fumes are toxic. Work outside or in an open garage.

- Pressure: The system is under pressure. Relieve it before opening lines.

FAQ About Essential Fuel System Components

What are the 5 components of a fuel system?

The 5 components of a fuel system include the fuel tank and the fuel pump. It also has a fuel filter, fuel lines, and fuel injectors. These parts store gas and move it to the engine.

What are the 6 basic components of the fuel injection system?

The 6 basic components of the fuel injection system are the tank, pump, and filter. It also uses a regulator, a rail, and injectors. They work as a team to power the car.

What are the 5 main components of the fuel injector?

The 5 main components of the fuel injector are the body and the coil. It also has a valve, a spring, and a nozzle. These parts spray the gas mist into the hot engine.

What are the four requirements of a fuel system?

The four requirements of a fuel system are to store gas and clean it. It must also move fuel with pressure and measure the flow. This helps the car engine run smooth and fast.

What are the main components of a fuel system?

The main components of a fuel system are the tank, pump, and lines. It also uses a filter, rail, and injectors. These parts move clean gas to the engine to make power.

Bottom Line: Understanding Your Fuel System

Your vehicle’s fuel system has seven essential components working together to deliver clean, pressurized fuel to your engine. Each part plays a critical role: the tank stores fuel, the pump pressurizes it, the filter cleans it, the regulator controls pressure, the rail distributes it, and the injectors spray it precisely into the engine.

Regular maintenance keeps your fuel system running efficiently. Replace filters on schedule, use quality fuel, and address problems early. Most fuel system issues start small—a weak pump, dirty injectors, or clogged filter—but can lead to expensive repairs if ignored.

Key takeaways:

- Seven main components: Tank, pump, filter, regulator, rail, injectors, lines.

- Maintenance matters: Replace filter every 20,000–40,000 miles.

- Watch for symptoms: Hard starting, rough idle, poor fuel economy.

- Cost range: $80–$2,000 depending on component and vehicle.

Taking care of your fuel system protects your engine, maintains performance, and saves money on fuel and repairs.