This article was updated in August 5, 2025 with new products and information by Mark S. Taylor

Ever turned the key on your rig and got nothing but silence? I’ve been there, standing in freezing weather with a dead battery and a full delivery schedule. Semi trucks don’t like sitting too long or dealing with extreme cold—especially when the batteries are worn down. Knowing how to jump start a semi truck engines safely isn’t just useful—it’s a must.

I’ve learned the hard way which tools work best, when to use a jump box, and why safety isn’t optional. In this guide, I’ll walk you through each step, share what’s worked for me, and break down the gear and precautions you need. Whether you’re new to diesel trucks or just want a refresher, I’ve got your back.

Contents

What Causes a Semi Truck to Have Starting Problems?

Answer: Semi trucks often don’t start because of weak batteries, cold weather, or loose wires.

If your semi truck won’t start, the battery is usually the first thing to check. Cold nights, long sits, or a small power drain can kill a battery fast. I’ve seen this happen over and over again—especially in winter.

One time, I had to jump a refrigerated trailer. The driver left the fridge unit on all night. By morning, the battery was dead, and the truck wouldn’t even click. That kind of thing sticks with you.

Other times, it’s not just the battery. Corroded terminals, loose grounds, or even bad wiring can stop a truck from starting. These problems aren’t always easy to spot, but they cause just as much trouble.

Now, I check my voltage often and keep the battery clean. It’s a small habit, but it’s saved me a lot of time and stress.

What Tools Do You Need to Jump Start a Semi Truck?

Answer: You need strong jumper cables or a heavy-duty jump box that works with 24-volt systems.

When I first started driving, I thought any jumper cable would do. I was wrong. Semi trucks need a lot more power than cars. Using the wrong tools can waste time—or worse—damage your truck.

A heavy duty jump starter is the safest and fastest way. It’s easy to use and doesn’t need another vehicle. I keep a jump box for semi truck in my cab. Mine has 2000 CCA, and it’s saved me more times than I can count.

If you use jumper cables, make sure they’re thick enough. The proper gauge jumper cables for semi truck is 1-gauge or thicker. Thin cables can melt or fail to start the engine. Trust me, I’ve seen it happen.

I always tell new drivers: invest in quality tools before you need them. A solid jump box and good cables can turn a bad day into a quick fix.

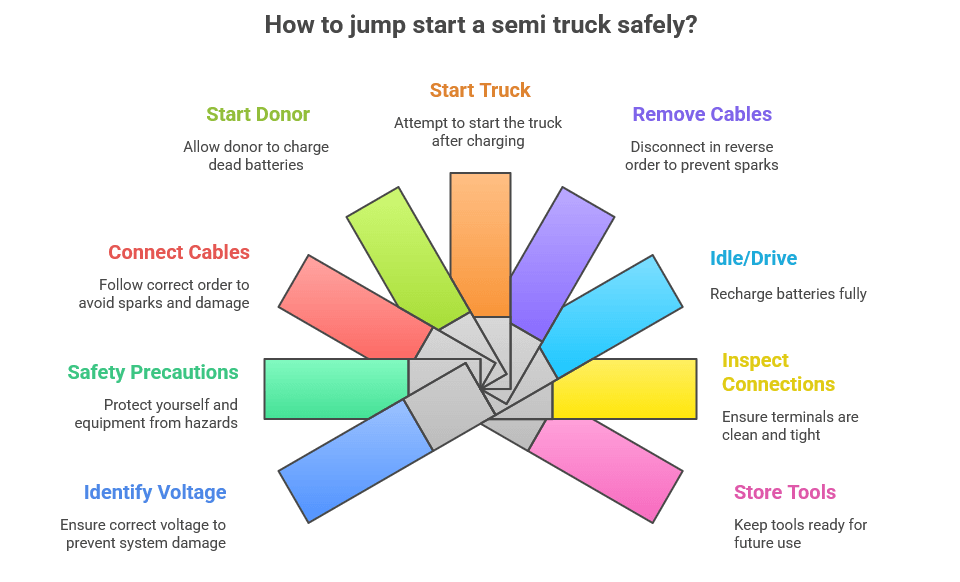

How to Jump Start a Semi Truck in 9 Steps

Answer: Follow these 9 steps in the right order to jump start your semi truck safely and avoid costly mistakes.

Step 1 – Identify Your Voltage System (12V or 24V)

Before doing anything, check if your truck runs on 12 volts or 24 volts. Most semi trucks use a 24V system with two 12V batteries in series. Using the wrong setup can fry your system fast.

I’ve seen drivers hook up 12V tools to a 24V system and blow fuses instantly. Always know your voltage before you start.

Step 2 – Take Safety Precautions Before Connecting

Jump starting a semi isn’t like boosting a car. There’s more power, more risk. Here are my key safety precautions jump starting semi truck:

- Wear gloves and safety glasses

- Turn off all accessories in both trucks

- Don’t lean over the batteries

- Double-check cable ends for rust or wear

A quick check saves you from big problems.

Step 3 – Connect the Jumper Cables Correctly

Attach the red (positive) clamp to the dead truck’s positive post. Then the red to the donor truck’s positive. After that, black (negative) to the donor’s negative post. Last, black to a grounded metal point on the dead truck.

If you’re using a jump box for semi truck, follow the same order.

One time, I rushed and reversed the cables. The spark was loud, and it scared me. I didn’t make that mistake again. Proper connection is key.

Keyword match: connecting jumper cables to truck battery

Step 4 – Start the Donor Truck or Jump Box

Let the donor truck or heavy duty jump starter run for a few minutes. This gives your dead batteries a bit of charge.

I usually wait five minutes before moving to the next step.

Step 5 – Try Starting the Semi Truck

Now, start your truck. If it cranks slowly, give it more time. If it doesn’t crank at all, check your connections again.

If it starts, let it idle for at least 10 minutes to recharge the batteries.

Step 6 – Remove the Jumper Cables in Reverse Order

Start with the black ground, then black from donor, then red from donor, and finally red from your truck.

Never let clamps touch during removal.

Step 7 – Let the Truck Idle or Drive It

Once it’s running, drive it or let it idle for at least 20 minutes. This gives the alternator time to recharge the batteries fully.

Step 8 – Inspect Battery Connections

Check that terminals are clean and tight. Loose cables can cause more semi truck starting problems later.

Step 9 – Store Your Tools

Wrap up your jumper cables or store your jump box for semi truck. Keep them clean, dry, and ready for next time.

Following this semi truck jump start procedure keeps things smooth and safe—no sparks, no stress.

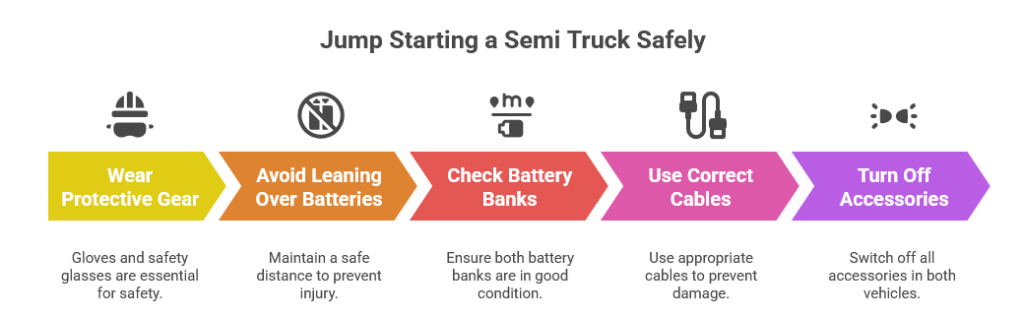

What Are Best Practices and Safety Tips?

Answer: To stay safe and protect your truck, always follow proper steps and use the right gear when jump starting.

Jumping a semi truck isn’t something you want to rush. These trucks carry a lot of power, and one wrong move can lead to injury or damage. I’ve seen guys burn their hands, fry wires, or even blow fuses because they skipped the basics.

Here’s what I always do before I boost a dead battery:

- Wear protective gear. Gloves and safety glasses are a must.

- Never lean over the batteries. If something sparks or explodes, you don’t want your face near it.

- Check both battery banks. One might be good, the other dead—especially in 24V setups.

- Use the right cables. Old or thin cables can melt or snap under load.

- Keep everything off. Make sure all lights, radios, and accessories are off in both vehicles.

These simple safety precautions jump starting semi truck systems have saved me from real trouble more than once. The goal isn’t just to get the truck running—it’s to do it without a trip to the hospital or the repair shop.

What If Jump Starting Fails?

Answer: If your truck still won’t start, check battery voltage and look for deeper electrical issues before trying again.

I’ve had times when even a solid jump didn’t work. When that happens, I don’t keep trying over and over. Instead, I grab my voltmeter and test the semi truck battery voltage. A healthy battery should read around 12.6V for each 12V battery. If it’s under 12V, it’s likely too weak to crank the engine.

Sometimes, the dead battery semi truck isn’t the only issue. A faulty alternator, corroded wires, or even a bad starter could be the real problem. I once spent an hour jumping a truck that had a bad ground wire—it wouldn’t start until I cleaned the contact point.

If the voltage checks out and the connections are solid, but the semi truck starting problems continue, I call for roadside help. No shame in it. It’s better than causing more damage or draining the batteries further.

Knowing when to stop and inspect saves time and money—and helps you avoid bigger breakdowns later.

How to Test Battery Voltage Before You Jump

Answer: Use a multimeter to check voltage—don’t waste time jumping a dead or damaged battery.

Before I try a jump, I always test each battery with a multimeter. A quick check tells me if the batteries just need a boost or if they’re totally dead. You want 12.6V or higher per battery. Anything below 12V means the battery’s struggling.

This small habit helps avoid pointless jump attempts and makes sure I fix the real issue—not just the symptoms.

Understanding 12V vs 24V Systems (And Why It Matters)

Answer: Most semi trucks use 24V systems—but mixing them with 12V gear can cause serious damage.

I’ve seen drivers fry electrical systems by connecting a 12V jump starter to a 24V battery setup. It’s a costly mistake that’s easy to avoid. Check your system before jumping. Two 12V batteries wired in series = 24V. Wired in parallel = 12V.

Know the setup before you connect anything. It’s one of the simplest ways to protect your truck.

When to Use a Jump Box vs a Second Truck

Answer: Use a jump box when you’re alone or need a fast, portable fix—use a second truck for longer cranks or heavy starts.

Both methods work, but they have different use cases. I carry a jump box because I don’t always have another truck nearby. It’s fast, clean, and safe. But if your batteries are deeply drained or it’s freezing out, a second running truck might give you a stronger push.

I’ve used both in the field, and each has its place depending on the situation. A jump box is great for solo drivers. A second truck is better for heavy loads or stubborn batteries.

Maintaining Battery Health in Semi Trucks

Answer: You can avoid most battery issues by doing regular checks and keeping things clean.

I’ve had my share of battery trouble. Over the years, I’ve learned that small steps make a big difference. A weak battery can leave you stuck, far from help.

Now, I check my batteries every week. I look for rust or white buildup on the terminals. If I see it, I clean it right away with a brush. I also check the semi truck battery voltage with a meter. If it’s low, I charge it before it dies.

Load testing helps too. Some batteries look fine but fail when the truck starts. Testing under load shows you the truth. I’ve found bad batteries this way before they let me down on the road.

These habits take minutes, but they keep my truck ready. Clean terminals, charged batteries, no surprises. It’s part of my routine now—and it works.

Frequently Asked Questions

How to jump-start a diesel truck?

To jump-start a diesel truck, connect jumper cables from a charged battery to the truck’s batteries. Start the donor, wait 5–10 minutes, then start the diesel truck. Make sure both systems match in voltage. This method works for most diesel truck batteries.

Is it okay to jump-start a diesel truck?

Yes, it’s safe to jump-start a diesel truck if you follow the right steps. Use heavy-duty jumper cables or a jump box and match the voltage system. Always follow safety rules to protect the batteries and electrical system during the jump-start process.

How to jump-start a dead truck battery?

To jump-start a dead truck battery, use jumper cables or a heavy-duty jump box. Connect positive to positive, negative to a metal ground. Start the donor vehicle, wait a few minutes, then try starting the truck. Remove cables in reverse order.

How to jump-start a 24V truck with a 12V battery?

Do not use a 12V battery to jump-start a 24V truck directly. It won’t supply enough power and may damage the system. Instead, use a 24V jump starter or two 12V batteries connected in series to match the 24V system. Always confirm the setup first.

How to start a diesel truck without batteries?

A diesel truck can’t start without working batteries. You need power for the starter and fuel system. If both batteries are dead, use a jump box or another truck to boost them. Push-starting doesn’t work on modern diesel trucks due to system demands.

My Final Thoughts on How to Jump Start a Semi Truck

If you’re someone who drives long hauls or works in cold weather, knowing how to jump start a semi truck is a must. But if you’re new to diesel engines or unsure about voltage systems, it’s okay to ask for help the first few times. I’ve learned this the hard way—freezing fingers, dead batteries, and all.

This guide is for folks who want to be prepared and stay on the road. It’s not about being perfect—it’s about being ready when things go quiet under the hood. Keep your tools handy, test your gear, and trust your routine. It’s worked for me, and I know it’ll work for you too.