This article was updated in January 2, 2026 with new products and information by Mark S. Taylor

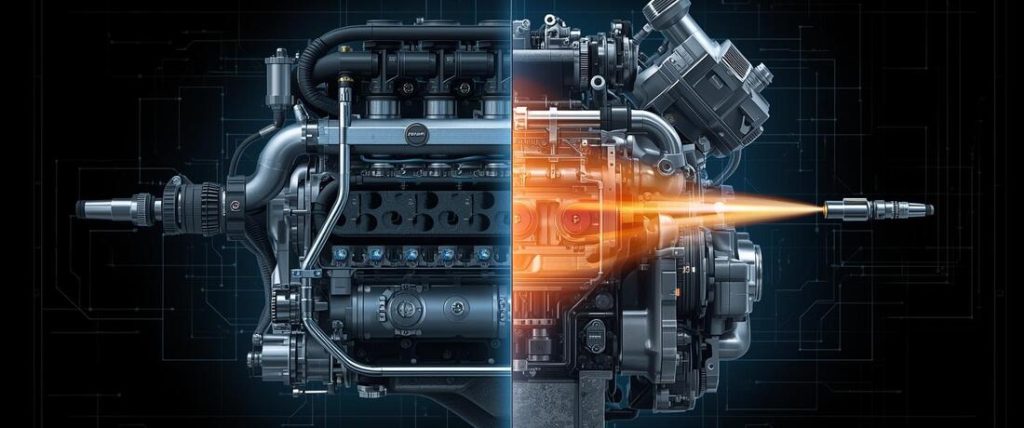

Common rail is a modern electronic fuel system that is quiet and efficient, while traditional direct injection is an older mechanical system known for being loud but simple.

Shopping for a diesel truck or just curious about your engine? You have likely heard the terms common rail diesel vs direct injection. It can get confusing. I have spent years working on both types. I know the pros and cons of each. In this guide, I will break down the differences. You will learn which one is better for towing, which costs less to fix, and which one you should buy. Understanding this helps you make smart choices for your truck.

Contents

What Is Direct Injection Diesel?

Direct injection is the old-school way to feed a diesel. It uses strong, simple parts. It’s a workhorse. This system ran most diesel trucks for a long, long time. You still find it in older rigs and some big gear. It is not fancy. But it gets the job done.

- It is a gear system. A pump on the engine pushes the fuel.

- One pump per part. Some have one pump for each spot where fuel goes in.

- Fuel goes right in. It shoots fuel straight into the spot where the fire is.

- Push is not super high. Fuel push is 5,000 to 10,000 PSI. It changes with how fast you go.

- No chips. It has almost no tech. It is all gears and parts.

- It has been here for ages. Most diesels from the 1900s to the early 2000s used it.

- Where to find it. Look for it in old trucks, big boats, and farm gear.

What Is Common Rail Diesel?

Common rail is the new way to feed a diesel. It is smart and fast. It uses one big pump to feed a pipe. That pipe sends fuel to all the fuel jets. A computer brain runs the whole show. This makes the engine strong, clean, and quiet. All new diesel trucks and cars use this.

- It is a chip system. A computer tells the fuel jets what to do.

- One pipe for all. One big pump feeds a pipe. The pipe gives fuel to all the jets.

- Push is super high. Fuel push is 20,000 to over 30,000 PSI. It stays the same all the time.

- A chip brain runs it. The Engine Control Unit (ECU) is in charge. It changes things on the fly.

- Many puffs of fuel. It can puff fuel into the engine many times in one go. This makes it run smooth.

- It is the new norm. All diesel rides since 2005 have this.

- Other names. You might hear it called CRDI.

Key Differences: A Side-by-Side Look

The big change is how fuel is pushed and controlled. Common rail uses a chip and super high push. Direct injection uses gears and less push. This one change makes a big difference in how the truck runs, sounds, and costs.

Fuel Push

Direct injection push is low. It is about 5,000 to 10,000 PSI. The push goes up and down with your speed. Common rail push is way higher. It is 20,000 to 30,000+ PSI. The push is always high. High push turns fuel into a fine mist. This mist burns up all the way. That means more get-up-and-go and more miles per gallon.

Control System

Direct injection uses gear time. A fuel pump is tied to the engine’s gears. This means you can’t change it much. Common rail uses a chip brain. The brain can change fuel time and amount right away. This makes the truck run its best at all times. It can fix for how high you are, how hot it is, or how much you pull.

Puffs of Fuel Per Go

Direct injection puffs fuel one time per go. It is one big blast of fuel. This can make the engine run rough and loud. Common rail can puff fuel a few times. It uses a small “pre” puff to start the fire soft. Then it adds the “big” puff for power. It may even add a “post” puff to clean the air out. This makes the engine run quiet and smooth.

Noise Level

Direct injection rigs are loud. They have that old “diesel knock.” That knock comes from the fast, rough fire of the fuel. Common rail rigs are much more quiet. The pre-puffs make the fire soft and slow. This stops the hard push that makes the knock. A new common rail diesel can be almost as quiet as a gas truck.

How Complex It Is

Direct injection rigs are simple. They have less stuff. They have almost no tech. This makes them easy to fix. Common rail rigs are not simple. They have a lot of sensors, chips, and high-pressure tech parts. This makes it hard to find a problem and fix it.

Good Things About Common Rail Diesel

Common rail rigs have a lot of good points. They make diesel trucks better in most ways. The big wins are in gas use, power, and clean air. That is why all brands use this tech now.

- Better gas use. They go about 10-20% further on a tank of gas.

- Cleaner air. They can pass the clean air rules. This is thanks to smart fuel control.

- Less noise. They have much less knock and shake.

- More get-up-and-go. Better fuel mist means a stronger fire. This gives more power from the same size engine.

- Smoother run. Many puffs of fuel make the engine run much more smooth.

- Better cold starts. They start up fast when it is very cold out.

- Smart control. The chip brain fixes for all things, like how high you are or how good the gas is.

- Cleaner pipe. They put out less black smoke when you step on it.

Bad Things About Common Rail Diesel

The high-tech side of common rail has bad points too. The main issues are cost and how complex it is. These rigs cost more to buy and to fix. They also do not like bad gas.

- High fix cost. A big fix can cost $2,000 to $5,000 more than on a direct injection rig.

- Complex tech. You need special tools to find a problem.

- Gas must be good. Bad gas can hurt the high-pressure parts fast.

- Fuel jets cost a lot. One jet can cost $300 to $800. A full set can be over $3,000.

- Pump can fail. If this pump fails, it can send metal bits all through the system. A new one is $1,500 to $3,000.

- Needs very clean gas. Water or dirt in the gas can cause very big cost problems.

- Not a DIY job. It is very hard for a home gear head to work on these.

- Needs a chip pro. Sometimes the problem is in the chip. You need a dealer or a pro to fix it.

Good Things About Direct Injection

The old-school direct injection has its own good side. Its big plus is that it is simple and cheap. These rigs are known to be tough and cheap to run. They are a top pick for folks who want a rig that is easy to fix.

- It is simple. It is much easier to find a problem and fix it.

- Fix cost is low. The gear parts cost much less than tech parts.

- Gas can be so-so. It is not as picky about dirty gas.

- You can fix it. A good home gear head can work on most any part of the engine.

- It is proven. These rigs have a long past of good, solid work.

- No chip needed. The engine can run with no complex tech.

- Fuel jets are cheap. A jet might only cost $100 to $300.

- Good for far-out spots. Any good diesel gear head, even in a small town, can fix it.

Bad Things About Direct Injection

The simple side of direct injection has a cost. These rigs are not as smooth or as good on gas. They also can’t pass the new clean air rules. That is why you don’t see them in new rides.

- It is loud. They have that “diesel knock” that a lot of folks do not like.

- Gas use is high. They use about 10-20% more gas than a common rail rig.

- Air is not as clean. They can’t pass the strict clean air rules we have now.

- Less get-up-and-go. Low fuel push means a less strong fire. This means less power.

- Black smoke. They often make more black smoke when you pull a big load.

- Hard to start in the cold. They can be a pain to start when it is very cold.

- Shakes at idle. They shake more than common rail rigs when they are just sitting still.

- Not smart. They can’t fix for things like how high you are or how hot it is.

Which Rides Use Each System?

It is good to know what system your ride has. It helps you know what it needs and what might go wrong. As a rule, how old the ride is the best clue. Almost all diesel rides made after 2005 use common rail. Older ones use direct injection.

Common Rail Diesel Rides

If you buy a new or almost new diesel, it has a common rail system. This is true for all new cars, trucks, and SUVs. The tech has been the norm for almost 20 years.

- Ford: The 6.0L, 6.4L, and 6.7L Power Stroke engines (2003 to now).

- GM: The 6.6L Duramax (2001 to now) and the 2.8L Duramax in the Colorado/Canyon.

- Ram: The 6.7L Cummins (from mid-2007) and the 3.0L EcoDiesel.

- European Cars: Most VW TDIs, BMWs, and Benz diesels from the late ’90s on.

- Light Trucks: Rides like the Chevy Colorado, GMC Canyon, and Jeep Gladiator.

- All of them. All diesel rides for people made since 2005 have this.

Direct Injection Diesel Rides

You will find direct injection in older rides and some big gear. These rigs are loved for being simple and tough. They are common in the used truck world.

- Older Trucks. Most Ford, GM, and Dodge trucks made before 2003.

- Classic Cummins. The famous 12-valve and early 24-valve Cummins engines (1989-2003).

- Boat Engines. Many boat engines still use this simple, solid system.

- Big Gear. A lot of build gear and farm gear still uses it.

- Military Rides. Many military rigs use it for its tough and simple ways.

- Pre-2005 Rule. Almost all rides made before 2005 will have this system.

Gas Use & Power: A Look

How do these systems change your daily drive? The change is clear. Common rail rigs are better on gas and have more power. Direct injection rigs are known for raw, simple pull. Let’s look at the numbers.

Gas Use

Common rail rigs get more miles per gallon. They use gas in a smarter way. In a truck, you can see a big change.

- Direct Injection. Older trucks might get 15-20 MPG on the road.

- Common Rail. Newer trucks can get 20-25 MPG on the road.

- The gain. This is a 15-25% jump in MPG.

- Real life. An early 2000s Duramax gets worse MPG than a 2010s Duramax.

Power

Common rail rigs make more power. The high push and smart brain give them an edge. They get more power from the same size engine.

- Direct Injection. Less power for its size. Less get-up-and-go for each bit of engine.

- Common Rail. Can make 20-30% more power from the same size engine.

- The why. Better fuel mist leads to a more full and strong fire.

- For example. A new 6.7L Power Stroke makes over 500 power. An old 7.3L Power Stroke made about 250 power.

Pulling Power

Both systems are great for pulling. That’s what diesel is for. But they do it a bit different.

- Both are good. Both can pull very big loads.

- Common Rail. They often have better low-end pull. This makes it easy to get a big load moving.

- Direct Injection. They have a name for being very solid for long hours of work pulls.

Care & How Well It Runs

Taking care of your diesel is key to a long life. The care needs for these two are not the same. Common rail rigs need more care and you must be on time. Direct injection rigs are more easy going.

Common Rail Care

To care for a common rail rig, you need clean gas. The high-pressure parts are very picky. You must be strict about care.

- Change the gas filter. This is a must. Change it every 10,000-15,000 miles.

- Fuel jet care. Jets may need care every 100,000-150,000 miles.

- High-pressure pump. This pump can fail between 100,000 and 200,000 miles.

- Use a gas helper. It is a good idea to use a gas helper. It helps with slickness and cleaning.

- Cost. Plan to pay $500-$2,000 a year to keep it safe.

Direct Injection Care

To care for a direct injection rig is more simple and cheap. The parts are more tough and less picky.

- Change the gas filter. Change it every 15,000-20,000 miles.

- Fuel jet care. Jets can last 150,000-200,000 miles.

- Injection pump. The main pump can last over 300,000 miles.

- Cost. Care costs about $200-$800 a year.

Known Problems

Each system has common problems. Knowing them can help you skip big fix bills.

- Common Rail. Watch for fuel jet failure, high-pressure pump (like the CP4) issues, and sensor problems.

- Direct Injection. Watch for pump wear, jets getting stuck, and “fuel knock” from bad time.

Fix Costs: A Look

When a part breaks, the fix cost is very different. Common rail parts cost a lot more. The work can also cost more because it is more complex.

| Part | Direct Injection Cost | Common Rail Cost |

|---|---|---|

| One Fuel Jet | $100 – $300 | $300 – $800 |

| Full Set of Jets | $400 – $1,200 | $1,500 – $4,000 |

| Injection/HP Pump | $500 – $1,500 | $1,500 – $3,500 |

| Find the Problem Fee | $50 – $100 | $100 – $300 |

| Work Cost Per Hour | $80 – $120/hr | $100 – $150/hr |

Which System Is Best?

There is no one “best” system. The right one for you depends on what you need. Think about how you will use the ride. Think about your fix budget and where you live.

Choose Common Rail If:

A common rail rig is the best pick for most folks now. It gives you a better drive.

- You are buying a new or new-ish diesel (made after 2005).

- You want the best MPG you can get.

- You need to pass new clean air tests.

- You like a ride that is quiet, smooth, and more slick.

- It will be a daily driver or a family ride.

- You can get to good diesel gear heads who know new tech.

Choose Direct Injection If:

A direct injection rig can be a great pick for some things. Its simple ways are its big plus.

- You are buying an older or classic diesel truck.

- You want simple ways and low fix bills.

- You are a DIY gear head who works on your own rides.

- You live far out with no dealers near you.

- You use it as a work truck and want solid, proven strength.

- You do not need to pass strict clean air tests.

Buying a Used Diesel: What to Look For

If you buy a used diesel, you need to look at it close. The problems you might find are not the same for each system. Here is a list of what to look for.

Common Rail Check

A used common rail truck can have hidden big cost problems. A good look is a must.

- Scan for codes. Use a scan tool to check for trouble codes. Look for codes like P0087 (low gas push) or P0200 (jet problem).

- Check filter past. Ask for proof of on-time gas filter changes. This is very key.

- Take it for a drive. Listen for any jet “knock” or misses.

- Look for leaks. Look close at the jets and gas lines for any signs of leaks.

- Check for pump updates. On some Ford 6.7L rigs, ask if the CP4 pump has been updated.

- Save for fixes. Set aside $2,000-$5,000 for fixes you might need.

Direct Injection Check

These rigs are simpler, but they can still have problems. Look for signs of wear and not being cared for.

- Listen for smoke. On a cold start, see if there is too much blue or white smoke.

- Check for leaks. Look at the pump and lines for any gas leaks.

- Take it for a drive. Get the engine hot and check for too much black smoke when you step on it.

- Look at the pump. Look at the main pump for any leaks or harm.

- Make sure it starts. Make sure it starts fast with no long cranking.

- Save for fixes. Set aside a smaller sum of $500-$2,000 for fixes you might need.

Common Problems & Fixes

Even with good care, problems can happen. Here are the most common issues for each system and how to fix them. For more in-depth care tips, check out our how to care for your diesel guide.

Common Rail Issues

These problems can cost a lot. The best fix is to stop them before they start.

- Fuel jet failure. When one jet fails, it is often best to change them all. This can cost $2,000-$4,000.

- High-pressure pump failure. This is the worst case. A bad pump can send metal bits all through the gas system. The fix can be $3,000-$8,000.

- Sensor problems. Sensors like the air flow or gas push sensors can fail. They cost less to fix, at $200-$800.

- Gas in the oil. A bad high-pressure pump can leak gas into the engine oil. This can ruin the engine.

- The fix. The best fix is to stop it. Always use good gas. Change your gas filters on time, every time.

Direct Injection Issues

These problems are often more simple and cheap to fix.

- Hard to start. This is often from bad jets or weak glow plugs. A fix can cost $400-$1,200.

- Black smoke. Too much black smoke can mean the time is off or the jets are worn. A fix is $300-$1,000.

- Injection pump wear. The pump can wear out over time. This causes low power and hard starts. A new one is $800-$2,000.

- The fix. Good care is key. Use good gas and fix small problems before they get big. You can learn more about how these rigs work from places like HowStuffWorks.

FAQ About Common Rail Diesel vs Direct Injection

What’s better, direct injection or common rail?

Common rail is better for MPG, power, and clean air. Direct injection is better for simple ways and low fix cost. The best pick depends on what you need and what you can spend.

Are common rail diesels direct injection?

Yes, they are a type of direct injection. “Common rail” is the name for the high-pressure gas system that feeds the direct jets.

What are the bad things about common rail?

The main bad things are high fix cost and how complex it is. It is also very picky about gas quality and needs special tools to find a problem.

What is common rail diesel?

It is a new fuel system. It uses one high-pressure pipe to feed all jets. A chip runs them for the best MPG and power.

Can you change a direct injection to a common rail?

You can, but it is very hard and costs a lot. You would have to change the whole gas system, add sensors, and put in a new chip brain. It is not a good idea for most folks.

The Final Word: New Power vs Old Simple

The choice between common rail and direct injection is a choice between two times of tech. Common rail is new power, MPG, and slick. Direct injection is old simple, tough, and low cost. There is no one win for all.

The final say:

- For new buyers. Common rail is your only pick. It is the law to meet clean air rules.

- For used buyers. A common rail is a great daily driver. A direct injection is a great work truck or a DIY job.

- Power. Common rail wins. It has more get-up-and-go, better MPG, and a smoother ride.

- How well it runs. It is a tie. Both are very solid when they are cared for the right way.

- Cost. Direct injection wins. It is much cheaper to fix and care for.

- What’s next. Common rail is the norm and will be. Direct injection is now an old tech.

Quick Summary

- Common Rail. New, quiet, and good on gas. Uses a chip brain and high push for more power.

- Direct Injection. Old, loud, and simple. Uses gear parts and is cheap to fix.

- MPG. Common rail gets 15-25% more MPG.

- Fix Cost. Common rail fixes can cost thousands. Direct injection fixes are much less.

- Best for daily driving. Choose a common rail for a smooth, quiet ride.

- Best for work trucks. Choose a direct injection for simple, tough strength.

- Key to long life. No matter the system, good care and clean gas are a must. For help picking the right truck for you, read our best trucks for pulling guide.